Oxidized Bitumen 95/25 Definition

Oxidized Bitumen 95/25 is Semi Solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. Special physical properties of its grade can be used in different applications in the construction business. Oxidized bitumen95/25 is based on petroleum bitumen which is made by oxidized bitumen 60/70 by very hot air. The numbers relate to the midpoint of the material’s softening point and penetration respectively. The softening point value is the degrees Centigrade measured by the Ring and Ball method as determined by ASTM D36. The penetration value is in 1/10 mm as determined by IP49 or ASTM- D5.

oxidized Bitumen is industrial bitumen which is dark, petroleum residue modified by the oxidation process. Oxidized Bitumen is produced by passing air through bitumen under controlled temperature conditions. Its consistency ranges from highly viscous to solid. Blown bitumen grade has technical advantages such as durability, flexibility, water resistant and chemical stability. There is the different grade of blown bitumen.

Blown Asphalt 95/25 Applications

Blown Asphalt 95/25 finds applications in various industries due to its specific properties. Some common applications include:

- Roofing: Used as a waterproofing agent for roofs in both residential and commercial buildings.

- Pavement Sealing: Applied to asphalt surfaces to enhance durability and weather resistance.

- Pipe Coating: Used for coating pipelines to protect against corrosion and environmental factors.

- Waterproofing: Applied to foundations, basements, and structures to prevent water infiltration.

- Joint Fillers: Used to fill joints and cracks in concrete structures to prevent water seepage.

- Soundproofing: Utilized as a soundproofing material in construction projects.

- Adhesives: Used as an adhesive in various industries, including automotive and construction.

- Paints and Coatings: Added to paints and coatings to improve adhesion and weather resistance.

These applications highlight the versatility and effectiveness of oxidized bitumen 95/25 in various construction and industrial settings.

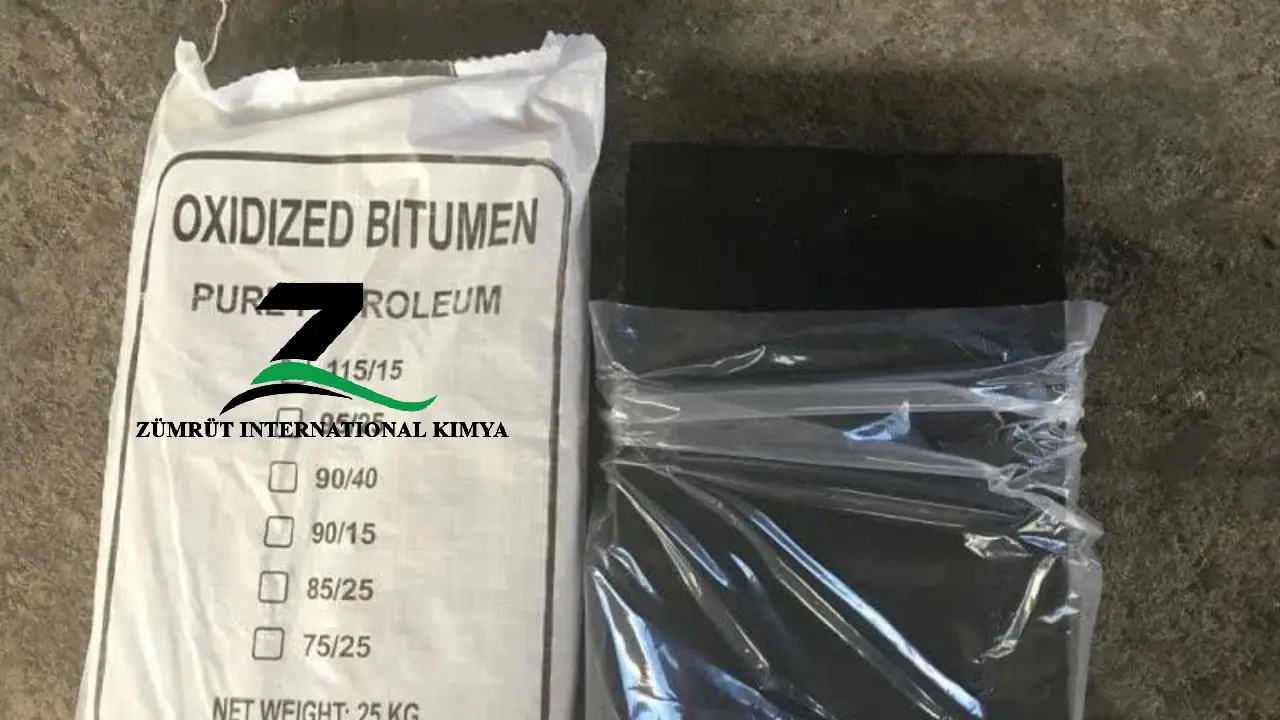

Blown Asphalt 95/25 Packing

ZUMRUT Co is the manufacturer of Oxidized Bitumen 95/25 in various packing, including bitumen 95/25 is available in 20 & 50 kg Kraft Paper Bags / Poly Amide Bags, 25 kg Carton box and 150, 180, 200kg Steel Drums. In addition, oxidized bitumen packing also palletize, 40 bags can stack on the pallet. 20 pallet can load to the 20ft container.

Recommendations for Handling / Storage of Oxidized Bitumen 95/25

Proper handling and storage of oxidized bitumen 95/25 are essential to maintain its quality and ensure safety. Here are some recommendations:

- Storage Conditions: Store oxidized bitumen 95/25 in a dry, well-ventilated area away from direct sunlight, heat sources, and open flames. Maintain storage temperatures within the recommended range to prevent degradation.

- Container Selection: Use appropriate containers made of materials compatible with bitumen, such as steel drums or tanks. Ensure that containers are clean, dry, and free from contaminants to avoid impurities in the bitumen.

- Handling Precautions: Wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and protective clothing, when handling oxidized bitumen to prevent skin contact and inhalation of fumes.

- Avoidance of Contamination: Prevent contamination of oxidized bitumen 95/25 by keeping storage areas clean and free from dust, dirt, and moisture. Use dedicated equipment and tools for handling and transferring bitumen to minimize the risk of contamination.

- Temperature Control: Monitor and control storage temperatures to prevent overheating or freezing of the bitumen. Avoid rapid temperature fluctuations, as they can affect the quality and consistency of the product.

- Ventilation: Ensure adequate ventilation in storage areas to disperse fumes and prevent the buildup of volatile gases. Install exhaust fans or vents to maintain airflow and minimize the risk of exposure to harmful vapors.

- Fire Safety: Implement fire prevention measures, including the installation of fire detection and suppression systems, as well as the provision of firefighting equipment such as extinguishers and sprinkler systems.

- Labeling and Identification: Clearly label containers with product information, handling instructions, and safety precautions. Use appropriate hazard symbols and signage to alert personnel to the presence of oxidized bitumen and associated risks.

Technical Advantages of Oxidized Bitumen 95/25

Oxidized bitumen 95/25 offers several technical advantages in comparison to other types of bitumen:

- Enhanced Durability: The oxidation process increases the hardness and resistance of the bitumen, making it more durable and suitable for long-term applications such as roofing and pavement sealing.

- Improved Weather Resistance: The oxidation process alters the molecular structure of the bitumen, enhancing its resistance to UV radiation, heat, and other environmental factors, thereby extending its service life.

- Superior Waterproofing Properties: Oxidized bitumen 95/25 forms a tight seal when applied, effectively preventing water penetration and protecting structures from moisture damage.

- Higher Softening Point: The higher softening point of 95°C compared to conventional bitumen indicates improved thermal stability, allowing it to withstand higher temperatures without softening or deforming.

- Reduced Thermal Expansion and Contraction: The enhanced thermal stability of oxidized bitumen 95/25 minimizes the risk of cracking and deformation due to temperature fluctuations, making it ideal for use in regions with extreme weather conditions.

- Excellent Adhesive Properties: Blown Asphalt 95/25 has excellent adhesive qualities, ensuring strong bonding with various substrates such as concrete, asphalt, and metal surfaces.

- Versatility: Its versatility allows it to be used in a wide range of applications, including roofing, pavement sealing, waterproofing, pipe coating, and adhesive formulations.

Technical Data Sheet of Oxidized Bitumen 95/25

| Bitumen 95/25 | Test method | Unit | Specification |

| Specific gravity @25/25 C | ASTM D70 | (Kg/m3) | 1.05 approx. |

| Penetration @ 25°c | ASTM D5 | mm/10 | 20/30 |

| Softening point °c | ASTM D36 | °C | 90/100 |

| Loss on heating(wt) % | ASTM D6 | Wt. % | 0.2 max |

| Flashpoint °c | ASTM D92 | °C | 250 min |

| Solubility is CS2(wt) % | ASTM D4 | Wt. % | 99.5 max |

| Ductility@25 C | ASTM D113 | — | 1.5 min |