WHAT IS SODA ASH?

Soda ash, also known as sodium carbonate (Na₂CO₃), is a white, odorless, water-soluble chemical compound. It is commonly used in various industrial processes, including the manufacturing of glass, detergents, and paper. All forms of this compound include white, odorless, water-soluble salts that produce moderately alkaline solutions in water. Historically, this substance was extracted from the ashes of plants grown in sodium-rich soils. Here are some key points about soda ash:

- Chemical Properties:

– Molecular Formula: Na₂CO₃

– Molar Mass: 105.99 g/mol

– Appearance: White, granular or powdered solid

– Solubility: Soluble in water, producing a strongly alkaline solution - Production:

– Sodium Carbonate can be produced through the Solvay process, which involves the reaction of sodium chloride (salt) and limestone (calcium carbonate) with ammonia.

– It can also be obtained from natural mineral deposits called trona or from sodium carbonate-rich brines.

THE HISTORY OF SODA ASH (SODIUM CARBONATE)

The history of soda ash, or sodium carbonate (Na₂CO₃), dates back thousands of years and spans various cultures and technological advancements. Here is a brief overview of its history:

Ancient Uses

1. Early Civilizations :

– Sodium Carbonate was known and used by ancient Egyptians as early as 3500 BCE. They extracted it from the ashes of certain plants and used it for making glass, as well as in mummification to preserve bodies.

– Ancient Romans used sodium carbonate for similar purposes, including glassmaking and as a cleaning agent.

2. Natural Sources :

– Naturally occurring soda ash was obtained from mineral deposits called natron, found in dry lake beds in regions like Egypt and the Middle East. Natron is a mixture of sodium carbonate decahydrate (Na₂CO₃·10H₂O) and sodium bicarbonate (NaHCO₃).

Medieval and Renaissance Periods

3. LeBlanc Process :

– In the late 18th century, the French chemist Nicolas LeBlanc developed the first industrial process for manufacturing soda ash from common salt (sodium chloride). The LeBlanc process involved converting sodium chloride to sodium carbonate through a series of chemical reactions involving sulfuric acid, limestone, and coal.

– This process greatly increased the availability of soda ash and lowered its cost, fueling the growth of industries like glassmaking, soap production, and textiles.

19th and 20th Centuries

4. Solvay Process :

– In 1861, the Belgian chemist Ernest Solvay invented a more efficient and environmentally friendly method for producing soda ash, known as the Solvay process. This process uses salt brine and limestone (calcium carbonate) with ammonia to produce sodium carbonate and calcium chloride.

– The Solvay process quickly supplanted the LeBlanc process and remains the primary method for manufacturing soda ash today.

5. Industrial Expansion :

– The availability of inexpensive soda ash from the Solvay process spurred further industrial growth. It became a key raw material for glassmaking, detergents, paper production, and various chemical manufacturing processes.

Modern Era

6. Natural Sources Revisited :

– In addition to the Solvay process, significant quantities of soda ash are mined from natural deposits of trona ore, particularly in the United States (notably in Wyoming). This natural soda ash is often more cost-effective and environmentally friendly to produce.

7. Environmental Considerations :

– Modern soda ash production, whether via the Solvay process or natural mining, incorporates environmental controls to reduce emissions and waste.

Current Applications

8. Versatile Uses :

– Today, Sodium Carbonate continues to be an essential industrial chemical with a wide range of applications, including glass manufacturing, water treatment, food processing, and as a raw material for various chemicals.

USES OF Sodium Carbonate

Sodium Carbonate, or sodium carbonate (Na₂CO₃), is a versatile chemical used in a wide range of industrial and domestic applications. Here are some of the primary uses of soda ash:

Industrial Uses

- Glass Manufacturing :

– Sodium Carbonate is a key ingredient in the production of glass. It helps reduce the melting temperature of silica, making the process more energy-efficient. It is used in the manufacturing of flat glass, container glass, and other glass products. - Detergents and Soaps :

– Soda ash acts as a builder in detergents, enhancing the effectiveness of the surfactants by softening the water. It is also used in the production of soap. - Water Treatment :

– Soda ash is used to adjust the pH of water, making it less acidic. This is important in municipal water treatment plants and for maintaining the balance in swimming pools. - Pulp and Paper Industry :

– Used in the pulping process to separate cellulose fibers and as a bleaching agent in paper production. - Chemical Manufacturing :

– Soda ash is a raw material for the production of numerous chemicals, including sodium bicarbonate (baking soda), sodium silicate, sodium tripolyphosphate, and others. - Textile Processing :

– Used in the dyeing and processing of cotton and other fabrics, soda ash helps to fix dyes to fibers and adjust pH levels in textile processes. - Metal Refining :

– Soda ash is used in the extraction of metals such as copper, zinc, and lead from their ores. - Food Industry :

– Used as a food additive (E500) to regulate acidity and as a leavening agent in baking.

Domestic Uses

- Cleaning Agent :

– Soda ash is used as a household cleaner for removing grease, oil, and stains from various surfaces. It is an ingredient in some laundry detergents and dishwasher detergents. - pH Adjustment :

– In home pools and aquariums, soda ash is used to maintain proper pH levels. - Baking :

– Though not as common as baking soda, soda ash can be used in baking to help dough rise.

Environmental Uses

- Flue Gas Desulfurization :

– Used to remove sulfur dioxide (SO₂) from the exhaust gases of fossil fuel power plants, helping to reduce air pollution. - Soil Remediation :

– Sodium Carbonate can be used to neutralize acidic soils, improving soil quality for agriculture.

Specialty Uses

- Oil and Gas :

– Used in drilling fluids to control the pH and alkalinity during the drilling of oil and gas wells. - Ceramics and Enamels :

– Sodium Carbonate is used in the production of ceramics and enamel glazes, helping to control the melting point and improve the final product’s quality.

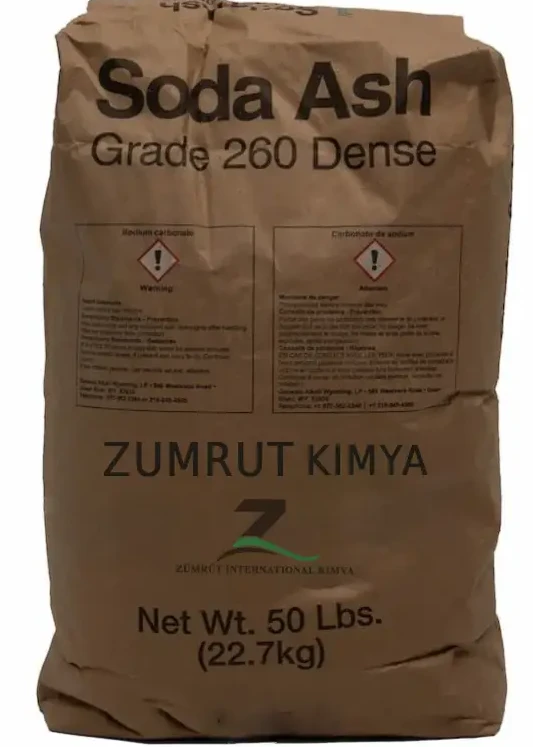

SODIUM CARBONATE PACKAGING

The packaging of light sodium carbonate and heavy sodium carbonate is available in the market in strong and strong bags with a weight of 50 kg. For bulk orders, side bags are also available, which are offered to the customer in a weight of 1000 kg.

20ft’

- Light (1000Kg. Jumbo bags): 16 mt

- Light (50Kg. Small bags) 17.2 mt

- Dense (1250Kg. Jumbo bags): 26mt

- Dense (50Kg. Small bags): 26 mt

40ft’

- Light (1000Kg. Jumbo bags): 25 mt

- Light (50Kg. Small bags): 20 mt

- Dense (1250Kg. Jumbo bags): 26.250mt

- Dense (50Kg. Small bags): 26.250mt

THE SAFETY OF SODA ASH

Sodium Carbonate, or sodium carbonate (Na₂CO₃), is generally considered safe when handled properly, but it can pose certain hazards that necessitate appropriate safety measures. Here are the key safety considerations:

Health Hazards

- Skin Contact :

– Soda ash can cause skin irritation upon contact. Prolonged or repeated exposure may lead to dryness or cracking of the skin. - Eye Contact :

– Soda ash is an irritant to the eyes. Direct contact can cause redness, pain, and potential damage to the cornea. - Inhalation :

– Inhaling soda ash dust can irritate the respiratory tract, leading to coughing, sneezing, and shortness of breath. Prolonged exposure may cause respiratory issues. - Ingestion :

– Ingesting soda ash can irritate the gastrointestinal tract, causing nausea, vomiting, and abdominal pain. Large quantities can be harmful.

Safety Measures

- Personal Protective Equipment (PPE) :

– Gloves : Wear protective gloves to prevent skin contact.

– Eye Protection : Use safety goggles or face shields to protect the eyes.

– Respiratory Protection : Use masks or respirators when handling soda ash in powder form or in situations where dust is generated.

– Clothing : Wear protective clothing to avoid skin contact. - Handling and Storage :

– Store soda ash in a cool, dry, well-ventilated area away from moisture. Containers should be tightly sealed to prevent exposure to air and moisture, which can cause it to clump.

– Use proper lifting techniques and equipment when handling large quantities to prevent physical strain. - Spill and Leak Procedures :

– In case of a spill, avoid creating dust. Clean up using appropriate tools (e.g., broom, vacuum) and place the material in a suitable container for disposal.

– Ensure adequate ventilation during cleanup. - First Aid Measures :

– Skin Contact : Rinse the affected area with plenty of water. Remove contaminated clothing and wash it before reuse.

– Eye Contact : Rinse eyes immediately with plenty of water for at least 15 minutes. Seek medical attention if irritation persists.

– Inhalation : Move the person to fresh air. If symptoms persist, seek medical attention.

– Ingestion : Do not induce vomiting. Rinse the mouth with water and seek medical attention if necessary.

Environmental Safety

Environmental Impact :

– Sodium Carbonate is not considered highly toxic to the environment. However, large releases can affect water pH and should be prevented.

– Avoid releasing large amounts into water bodies or soil to prevent ecological imbalances.

SPECIFICATION OF SODA ASH(LIGHT)

| CHEMICAL COMPOSITION | UNIT | MIN | MAX | |

| SODIUM CARBONATE | %wt | 99.2 | 99.6 | |

| SODIUM CHLORIDE | %wt | 0.3 | 0.4 | |

| SODIUM BICARBONATE | %wt | — | 0.1 | |

| SODIUM SULFATE | %wt | — | 0.05 | |

| IRON | Ppm | 30 | 40 | |

| LOSS ON HEAT | %wt | — | 0.2 | |

| MOISTURE | %wt | — | 02 | |

| Ni | Ppm | — | 30 | |

| Cr | Ppm | — | 10 | |

| Mn | Ppm | — | 10 | |

| Cu | ppm | — | 30 | |

| Chemical Composition | Unit | Min | Max | |

| Total Alkalinity | %wt | 58.12 | 58.42 | |

| Pouring density | g/cm3 | 0.45 | 0.60 | |

| <40 | %wt | — | 40 | |

| 40-140 | — | 59 | ||

| >140 | — | 1 | ||

SPECIFICATION OF SODA ASH(LIGHT)

SPECIFICATION OF SODA ASH(DENSE)