Description of Oxidized Polyethylene Wax (OPE Wax)

Oxidized Polyethylene Wax (OPE Wax) is a high-performance, modified polyethylene wax that has undergone a controlled oxidation process to introduce functional polar groups, such as hydroxyl and carboxyl groups, into its structure. This modification enhances its compatibility with polar resins and improves its dispersibility, lubricity, and emulsifiability.

OPE Wax is a white, odorless solid with excellent thermal stability, low volatility, and strong hardness. It offers both internal and external lubrication properties, making it widely used in various industrial applications.

Key Features:

- Excellent lubrication and dispersing performance

- High gloss and improved surface finish

- Good thermal stability and anti-blocking characteristics

- Enhanced compatibility with polar materials (e.g., PVC, EVA, rubber)

- Emulsifiable grades available for aqueous systems

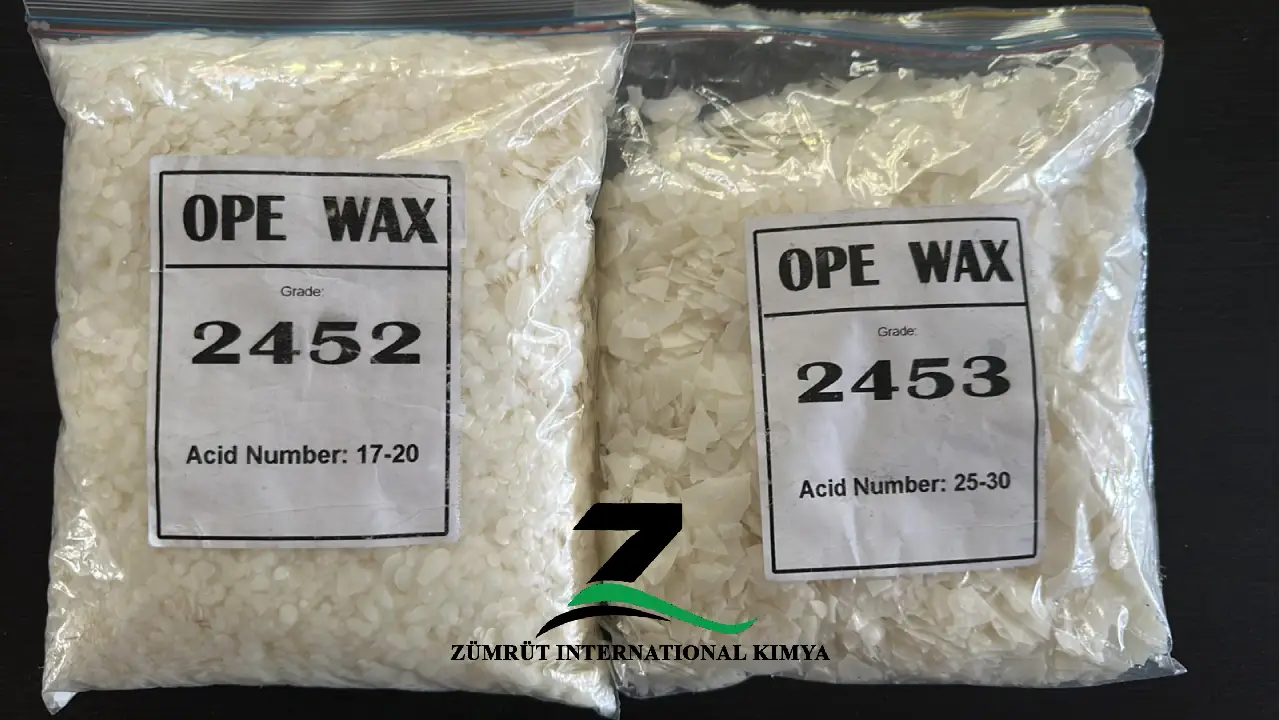

Main Grades of Oxidized polyethylene Wax

1. Low Acid Value Grade (AV ≤ 10 mg KOH/g)

- Description: Contains fewer polar functional groups, offering moderate oxidation.

- Features: Excellent external lubrication, high gloss, and low viscosity.

Applications:

- PVC extrusion and injection molding

- Masterbatch and filler dispersions

- PE and PP processing

2. Medium Acid Value Grade (AV 10–20 mg KOH/g)

- Description: Balanced oxidation level that provides both internal and external lubrication.

- Features: Good dispersibility, thermal stability, and improved compatibility with polar resins.

Applications:

- PVC stabilizers and lubricants

- Hot melt adhesives

- Printing inks and coatings

3. High Acid Value Grade (AV ≥ 20 mg KOH/g)

- Description: Highly oxidized with a greater number of polar groups for strong adhesion and emulsifiability.

- Features: Excellent emulsifying property and strong bonding with polar materials.

Applications:

- Emulsion waxes for textiles, leather, and polishes

- Water-based coatings and paints

- Paper surface treatment

4. Emulsifiable Oxidized PE Wax

- Description: Specially formulated for water-based systems; forms stable emulsions.

- Features: Fine particle size, high stability, and excellent gloss finish.

Applications:

- Floor and furniture polishes

- Textile softeners

- Water-based inks and coatings

5. High-Density and Low-Density Grades

- High-Density (HD-OPE Wax): Harder, higher melting point (110–120 °C), suitable for rigid PVC and engineering plastics.

- Low-Density (LD-OPE Wax): Softer, lower melting point (90–105 °C), ideal for flexible PVC and wax emulsions.

Application of Oxidized Polyethylene Wax

Oxidized Polyethylene Wax has application in different industries such as Plastics Industry, Rubber Industry, Coatings and Paints, Textiles and Leather, Hot-Melt Adhesives and Cable and Wire Industry.

OPE Wax Packing

The most common packing of OPE Wax is 25 Kg BOPP Bags.

Supplier of Oxidized polyethylene wax

At Zümrüt İnternational Kimya Co., we are a manufacturer and supplier of oxidized polyethylene wax, tailored to the needs of various industries. We can produce the above types of Wax according to the customer’s request with the acidity and viscosity they desire and deliver them to the destination ports.

Specification of Oxidized Polyethylene Wax (OPE Wax )

| Product | Viscosity | Drop point | Penetration | Acid value |

| @ 140°C [mm²/s] | [°C] | [0.1 mm] | [mg KOH/g] | |

| ZÜMRÜT OPE WAX 253 | 200 | 109 | ≤ 2 | 16 |

| ZÜMRÜT OPE WAX 252 | 200 | 106 | ≤ 3 | 16 |

| ZÜMRÜT OPE WAX 272 | 170 | 108 | ≤ 3 | 22 |

| ZÜMRÜT OPE WAX 271 | 170 | 104 | ≤ 4 | 22 |

| ZÜMRÜT OPE WAX 262 | 150 | 107 | ≤ 4 | 27 |

| ZÜMRÜT OPE WAX 261 | 150 | 103 | ≤ 5 | 27 |

| ZÜMRÜT OPE WAX 2628 | 50 | 105 | ≤ 6 | 27 |

Specification of ZÜMRÜT Oxidized Polyethylene Wax

Technical Data Sheet of Oxidised Polyethylene Wax 261(OPE Wax 261)

| Characteristics | Reference Value | Units | Test Method |

| Acid Value* | 25-29 | mg KOH/g | DGF M-IV 2 |

| Viscosity @ 140°C * | 100-200 | mm2/s | DGF M-III 8 |

| Drop Point * | 100-105 | °C | DGF M-III 3 |

| Solidification Point | 90-95 | °C | DGF M-III 4a |

| Needle Penetration | ≤ 5 | 10-1 mm | DGF M-III 9b |

| Density | 0.94-0.96 | g/cm3 | DIN EN ISO 1183, C |

| Molecular weight (Mn) | 1400 | g/mol | GPC |

| Saponification value | > 45 | mg KOH/g | DGF M-IV 2 |

| Type of delivery | Fine grain | – | Visual |

| Appearance | White-yellowish | – | Visual |