Gilsonite Modified Asphalt

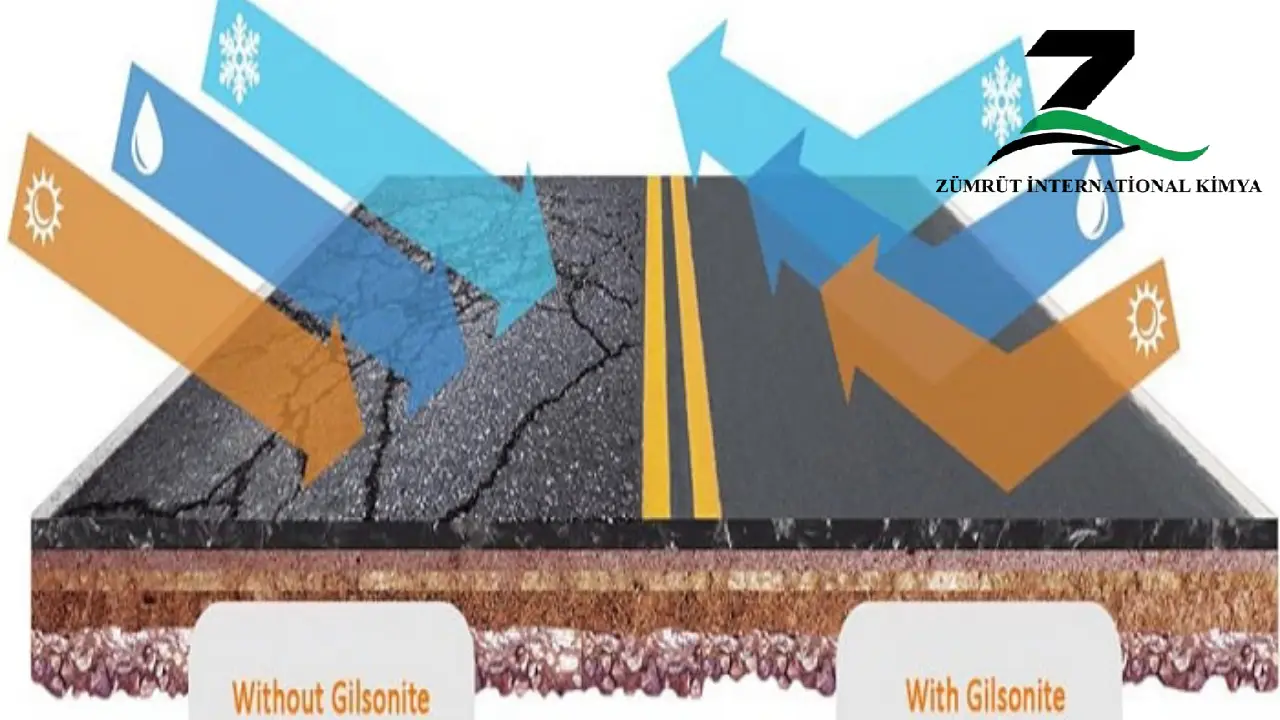

Gilsonite Modified Asphalt (GMA) is a type of asphalt mixture that includes Gilsonite, a naturally occurring solid hydrocarbon. This modification enhances the performance characteristics of the asphalt, making it more durable and resistant to various forms of distress.

Gilsonite Modified asphalt has various benefits such as good workability and durability. It is one of the most general materials used as asphalt mixtures in road pavements. Asphalt mixtures and binders can be improved by modifying them with various additives. Gilsonite is a natural asphalt hydrocarbon which may be used as an additive to hot mix asphalt. It is used as an asphalt binder modifier (wet process) and an asphalt mixture modifier (dry process) to improve the properties of the mix. It provides the option of improved rheological properties, stability, strength rutting resistance and moisture sensitivity.

Key benefits of using Gilsonite in asphalt include

- Increased Durability : Gilsonite improves the overall strength and stiffness of the asphalt, extending its lifespan.

- Enhanced Rutting Resistance : The addition of Gilsonite helps the asphalt resist deformation under heavy traffic loads.

- Improved Fatigue Resistance : GMA is better able to withstand repeated loading cycles, reducing the risk of cracking.

- Higher Temperature Stability : Gilsonite-modified asphalt can perform well in both high and low-temperature environments.

- Resistance to Water Damage : The modified asphalt exhibits better resistance to moisture penetration, which can lead to pavement deterioration.

These properties make Gilsonite Modified Asphalt a preferred choice for high-stress applications such as highways, airports, and heavy-duty industrial pavements.

Gilsonite Benefits-Modified Asphalt – Gilsonite is superior for recycling asphalt

Gilsonite is particularly beneficial in the context of recycling asphalt for several reasons:

- Improved Binder Properties : When Gilsonite is added to recycled asphalt pavement (RAP), it rejuvenates the aged binder, restoring its original properties and improving the performance of the recycled mix.

- Enhanced Durability : Gilsonite contributes to the overall strength and durability of recycled asphalt, leading to longer-lasting pavements that can better withstand traffic loads and environmental conditions.

- Increased Stability : The addition of Gilsonite improves the stability of recycled asphalt mixes, reducing the likelihood of rutting and deformation over time.

- Cost-Effectiveness : Utilizing Gilsonite in recycled asphalt can lower costs by reducing the need for new materials while extending the life of existing pavements.

- Environmental Benefits : By improving the performance of recycled asphalt, Gilsonite supports sustainability efforts by reducing waste and the demand for new asphalt production.

- Reduced Cracking and Maintenance : Gilsonite enhances the flexibility and resistance to thermal cracking in recycled asphalt, leading to lower maintenance costs and fewer repairs.

Application of (GMA)

The application of Gilsonite Modified Asphalt (GMA) involves several steps, which ensure that the enhanced properties of the asphalt are effectively utilized. Here’s a detailed look at how GMA is typically applied:

- Material Preparation :

– Aggregate Selection : Choose suitable aggregates that meet the specifications for the intended application.

– Gilsonite Addition : Gilsonite is typically added to the asphalt binder. This can be done by mixing Gilsonite into the hot liquid asphalt binder before it is combined with the aggregate. - Mix Design :

– Laboratory Testing : Conduct laboratory tests to determine the optimal mix design. This includes testing for stability, durability, workability, and performance characteristics.

– Proportioning : Properly proportion the Gilsonite, asphalt binder, and aggregates to achieve the desired performance characteristics. - Mixing Process :

– Hot Mix Asphalt Plant : Produce the Gilsonite modified asphalt at a hot mix asphalt plant. The process involves heating the aggregates and asphalt binder (with Gilsonite) to the appropriate temperature, ensuring a thorough mix.

– Quality Control : Implement quality control measures to ensure the consistency and quality of the mix. - Transportation :

– Transport the hot mix from the plant to the job site using insulated trucks to maintain the temperature of the mix. - Pavement Construction :

– Surface Preparation : Ensure the existing surface is properly prepared, which may include cleaning, leveling, and applying a tack coat to enhance bonding.

– Placement : Use pavers to place the Gilsonite modified asphalt mix on the prepared surface. Ensure the mix is placed uniformly and at the correct thickness.

– Compaction : Compact the asphalt mix using rollers while it is still hot to achieve the desired density and smoothness. Proper compaction is crucial for the performance and longevity of the pavement. - Finishing :

– Surface Finish : Ensure a smooth finish and check for any surface defects. Adjustments can be made during the compaction process.

– Curing : Allow the pavement to cool and cure before opening it to traffic. The curing time can vary depending on the ambient temperature and the specific mix used. - Maintenance :

– Regularly inspect and maintain the pavement to extend its service life. GMA pavements typically require less maintenance due to their enhanced properties, but routine checks for any issues such as cracks or deformations are still important.

By following these steps, Gilsonite Modified Asphalt can be effectively applied to various infrastructure projects, providing enhanced performance and durability.

Economic and Environment Assessment (GMA)

The criteria considered in this for the assessment of economic and environmental aspects are the use of Gilsonite alone and in combination with other additives in the asphalt industry.

From the economic perspective, the better quality and longer life of pavements satisfy both safety and economical aspects . The use of Gilsonite improves asphalt mixture resistance against tensile stresses, resulting in an increase in the service life of the pavement and a reduction in repair and maintenance costs . Likewise, Gilsonite is an appropriate alternative and economical choice for enhancing the properties of the binders ; for example, Gilsonite is less expensive compared with other modifiers such as SBS or EVA (Ethylene-Vinyl-Acetate). According to the resilient modulus results, Gilsonite demonstrated higher performance compared to asphalt mixtures made with pure asphalt binder. This outcome could have a significant influence on the economic design of roads because of the need in asphalt pavements to have resilient modulus. Moreover, the increased resilient modulus of the mixtures containing Gilsonite may reduce the asphalt layer thickness, resulting in improved resistance to heavy traffic loads, and extended service life of the pavement.

From an environmental perspective, the asphalt industry process plays an important role in contributing to the causes associated with global greenhouse gas emissions. Therefore, asphalt industries are actively searching for alternative materials and techniques in order to move towards sustainable development. Considering the amount of recycled material included in the asphalt mixture, Gilsonite increases the performance of the porous HMA when using 100% recycled concrete as aggregate ]; therefore, it is a potential material for sustainable pavement systems. However, adding Gilsonite to the asphalt binder decreases the penetration value and increases the SP and viscosity. This leads to increased mixing and compaction temperatures, resulting in increased energy consumption and associated CO2 emissions. This can be prevented by using Gilsonite with an asphalt binder modified with Sasobit. Furthermore, the DSR test indicated that the use of Gilsonite resulted in lower viscosity than SBS, and thus Gilsonite offers energy consumption advantages. Ultimately, the evaluation of the environmental impacts and economic feasibility of asphalt mixtures containing Gilsonite indicates that adding Gilsonite in combination with other selective additives provides more economic and environmental advantages. However, more research is needed to consider the economic and environmental perspectives fully; the cost-effectiveness and carbon footprint of using Gilsonite as an asphalt modifier needs further investigation since only a few publications considered this aspect.