Gilsonite Water Based Mud Additive Description

Gilsonite Water Based Mud, it is essential to have a FLUID LOSS CONTROL agent which is solvable in water. Sulfonated Gilsonite possesses this characteristic while the Gilsonite does not. Therefore having the correct formula and composition to make the Sulfonated Gilsonite is the key factor in supplying FLC to water based muds. Using Gilsonite in its Sulfonated form provides an easy mixing during the mud making and decreases the differential sticking significantly. In addition, the Sulfonated Gilsonite causes better lubricity and flow. Sulfonated Gilsonite is solvable both in Water and Oil matters in order to be applied to all drilling muds; yet applying to Water based muds are suggested.

Gilsonite, also known as natural bitumen, is a solid hydrocarbon resin found in the Uintah Basin of northeastern Utah. When used as an additive in water-based drilling muds, Gilsonite offers several key benefits that enhance the performance and efficiency of drilling operations.

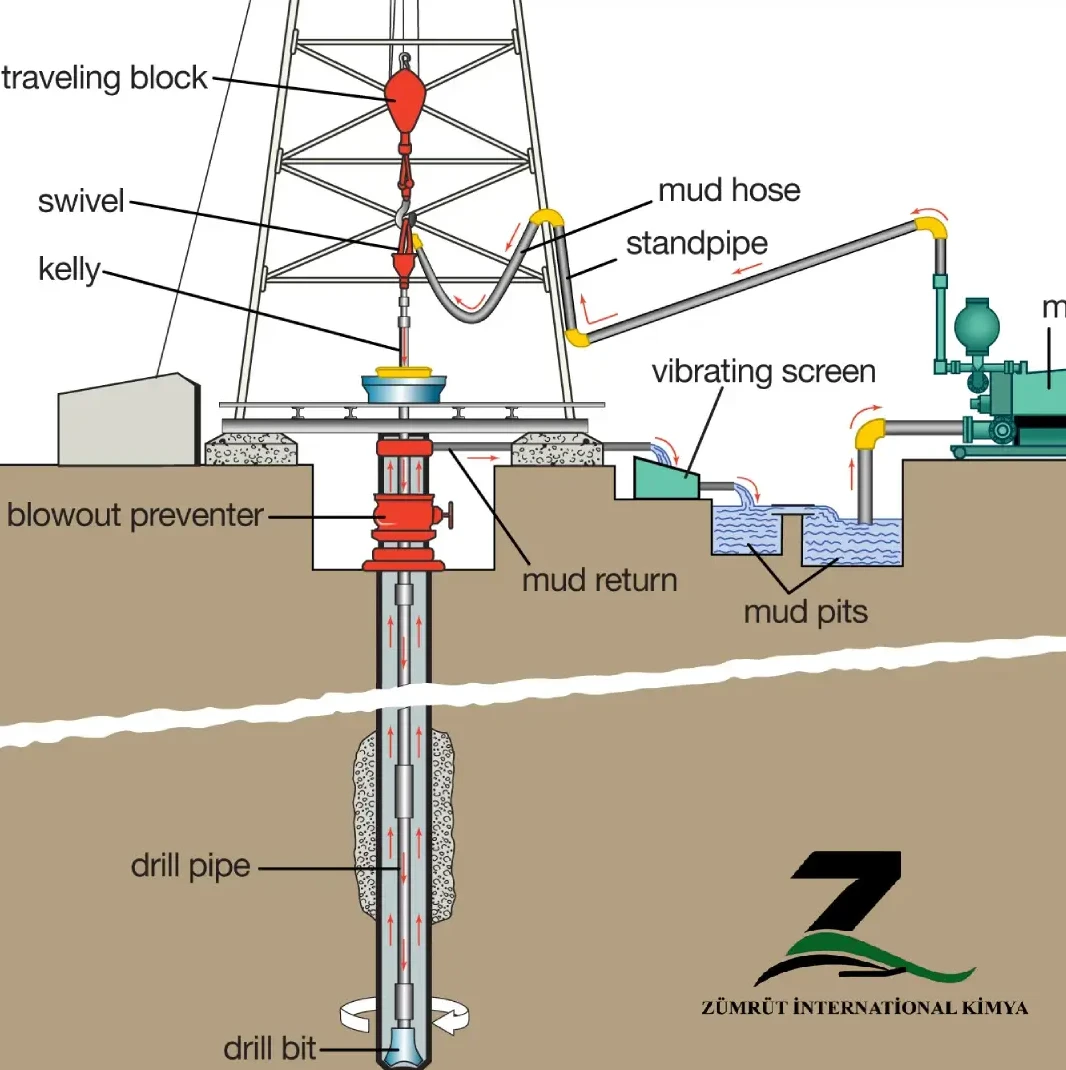

In drilling rigs, a mud must be applied to the driller for more effective drilling and also to reduce the temperature of the hole. A drilling mud is a lubricant applied in this process.

There are basically three types of Drilling Muds:

drilling muds, also known as drilling fluids, are generally classified into three main types based on their base fluid:

- Water-Based Muds (WBMs) :

– Description : These muds use water or a water-based solution as the primary fluid. They are the most commonly used drilling fluids due to their cost-effectiveness and environmental friendliness.

– Components : WBMs typically consist of water mixed with various additives such as clays (bentonite), polymers, and weighting agents to enhance their properties.

– Applications : Suitable for a wide range of drilling conditions, including shale formations, geothermal wells, and areas where environmental regulations are strict.

– Benefits : Cost-effective, easier disposal, environmentally friendly, and less complex to formulate. - Oil-Based Muds (OBMs) :

– Description : These muds use oil or synthetic-based fluids as the primary fluid. They offer superior performance in certain challenging drilling conditions.

– Components : OBMs typically consist of diesel, mineral oil, or synthetic fluids, mixed with emulsifiers, wetting agents, and other additives.

– Applications : Ideal for drilling through reactive shales, high-temperature and high-pressure wells, and formations that are sensitive to water.

– Benefits : Excellent shale inhibition, high thermal stability, better lubrication, and reduced risk of differential sticking. - Synthetic-Based Muds (SBMs) :

– Description : These muds use synthetic base fluids, designed to offer the performance advantages of oil-based muds while being more environmentally friendly.

– Components : SBMs typically consist of synthetic oils like esters, olefins, or paraffins, combined with similar additives used in OBMs.

– Applications : Used in environmentally sensitive areas where the discharge of traditional oil-based muds is restricted, as well as in high-temperature and high-pressure wells.

– Benefits : Environmentally friendly compared to OBMs, excellent performance in challenging drilling conditions, high thermal stability, and better lubrication.

Key Benefits and Functions:

- Shale Stabilization :

– Mechanism : Gilsonite helps stabilize shale formations by preventing hydration and swelling. This is particularly important when drilling through water-sensitive shales that can expand and disintegrate upon contact with water-based fluids.

– Outcome : Reduced risk of wellbore instability and collapse. - Fluid Loss Control :

– Mechanism : It forms an impermeable filter cake on the wellbore wall, which significantly reduces the loss of drilling fluids into the surrounding formation.

– Outcome : Maintains the hydrostatic pressure necessary for safe and efficient drilling. - Lubrication and Friction Reduction :

– Mechanism : Gilsonite acts as a lubricant, reducing the coefficient of friction between the drill string and the wellbore.

– Outcome : Enhances drilling efficiency, reduces torque and drag, and minimizes wear on drilling equipment. - Wellbore Strengthening :

– Mechanism : By plugging microfractures and pore spaces in the formation, Gilsonite strengthens the wellbore.

– Outcome : Prevents wellbore collapse and improves overall wellbore stability. - Thermal Stability :

– Mechanism : Gilsonite is thermally stable and can withstand the high temperatures encountered in deep drilling operations.

– Outcome : Suitable for a wide range of drilling environments, including high-temperature wells.

Applications Gilsonite Water Based Mud Additive

Specific Drilling Scenarios:

- Oil and Gas Exploration :

– Application : Used in exploratory wells to manage unknown formations and varying geological conditions.

– Benefit : Improves wellbore stability and fluid loss control, reducing operational risks and costs. - Horizontal and Directional Drilling :

– Application : Enhancing the properties of drilling fluids used in complex well paths.

– Benefit : Reduces friction and drag, facilitating smoother drilling operations and improving the rate of penetration. - Geothermal Drilling :

– Application : Suitable for high-temperature geothermal wells where conventional additives may degrade.

– Benefit : Provides thermal stability, ensuring consistent performance of drilling fluids under extreme heat. - Underbalanced Drilling :

– Application : Used in scenarios where maintaining lower wellbore pressures is critical.

– Benefit : Helps to prevent formation damage and control fluid loss, maintaining wellbore stability. - Workover and Completion Operations :

– Application : Utilized during workover and completion to stabilize the wellbore and control fluid loss.

– Benefit : Ensures the integrity of the wellbore during these critical phases, improving the success rate of completions and reducing operational downtime.

Form and Usage:

- Form : Gilsonite is typically available in powdered or granular form, making it easy to mix with water-based drilling fluids.

- Usage : The concentration of Gilsonite in the drilling mud can vary depending on the specific drilling conditions and requirements. It is usually added to the mud system at the surface during the mixing process.

In summary, Gilsonite water-based mud additive is a versatile and valuable component in drilling operations, providing enhanced shale stability, fluid loss control, lubrication, wellbore strengthening, and thermal stability. These benefits contribute to safer, more efficient, and more cost-effective drilling processes.

Gilsonite Friendly to Water

Water-based Gilsonite is natural bitumen environmentally safe and specially formulated to protect hole shale water base drilling. The drilling fluid serves a number of functions including taking heat away from the drill bit and facilitating the return of drill cuttings to the surface.

The present invention deals with the consequences of using water-based drilling Gilsonite muds. When the hydrostatic pressure of the drilling mud in the wellbore exceeds the inwardly acting pressure of the surrounding formation, the drilling mud is forced into the surrounding formation through the walls of the wellbore.

In many applications the drilling Gilsonite mud is intended to be deposited in and/or on the wellbore wall, forming so called “filter cake” which, amongst other things, helps to limit the invasion of formation fluids into the wellbore; reduces the risk of the wellbore collapsing during drilling; and resists the escape of drilling fluids into the formation.